Introduction

In the world of fabrication, custom aluminum welding stands out as a versatile and efficient method for creating strong, lightweight structures. Whether you're crafting intricate designs or robust frameworks, understanding the nuances of aluminum welding can elevate your projects to new heights. With its unique properties, aluminum not only offers aesthetic appeal but also provides durability and resistance to corrosion, making it a popular choice among fabricators.

Understanding Custom Aluminum Welding

Custom aluminum welding refers to the specialized techniques employed to join aluminum components through various welding types. This process requires a keen understanding of both the material's characteristics and the specific requirements of each project. By mastering techniques like MIG and TIG welding, welders can produce high-quality aluminum weldments tailored to meet diverse client needs.

Benefits of Aluminum in Fabrication

Aluminum is celebrated in the fabrication industry for its remarkable strength-to-weight ratio, which allows for lighter constructions without sacrificing structural integrity. Its natural resistance to corrosion makes it ideal for outdoor applications and environments where moisture is prevalent. Additionally, custom aluminum welding enhances design flexibility, enabling engineers and designers to bring their most inventive ideas to life while ensuring longevity through reliable joints.

Key Applications for Custom Aluminum Welding

The applications for custom aluminum welding are extensive and varied across multiple industries. From marine applications such as yacht fabrication to architectural innovations that redefine skylines, aluminum weldments play a crucial role in modern construction and design. Furthermore, inventive products ranging from automotive components to aerospace parts showcase how effective aluminum to aluminum welding can be in producing high-performance items that stand out in both functionality and style.

The Basics of Aluminum Welding

Aluminum welding is a fascinating realm of fabrication that requires a solid understanding of various welding types and techniques. Whether you're crafting custom aluminum weldments or embarking on a larger project, knowing the basics can make all the difference in achieving high-quality results. This section will explore the different welding processes, compare MIG and TIG methods, and guide you in choosing the right approach for your specific needs.

Overview of Welding Types

When diving into custom aluminum welding, it's essential to familiarize yourself with the various welding types available. Each method has its unique advantages and is suited for different applications, especially when it comes to aluminum to aluminum welding. From arc welding to laser techniques, understanding these options will help you determine which type aligns best with your project's requirements.

One of the most popular methods for aluminum welding is MIG (Metal Inert Gas) welding, known for its speed and versatility. Alternatively, TIG (Tungsten Inert Gas) welding offers precision and control but requires more skill and practice. Regardless of the method chosen, mastering these fundamentals will set you up for success in creating durable aluminum weldments.

Comparing MIG and TIG Welding

MIG and TIG are two heavyweights in the world of aluminum welding, each bringing something unique to the table. MIG welding is often favored for its speed; it's perfect when you're looking to get projects done quickly without compromising too much on quality. On the other hand, TIG welding shines in situations where precision is key—think intricate designs or thin materials where every detail counts.

When comparing these two methods specifically for custom aluminum welds, consider factors like ease of use and material thickness. While MIG may be easier for beginners due to its straightforward operation, experienced welders often prefer TIG when working on thinner materials or needing a cleaner finish. Ultimately, your choice should reflect both your skill level and project demands.

Choosing the Right Process for Your Project

Selecting between MIG and TIG can feel daunting at first glance; however, breaking down your project’s requirements simplifies this decision-making process significantly. If you’re working on large-scale projects that demand speed—such as automotive parts or structural components—MIG might be your go-to method due to its efficiency in handling thick sections of metal during custom aluminum welding tasks.

Conversely, if you're tackling detailed work like artistic sculptures or precise components that require clean seams with minimal cleanup afterward, then investing time into mastering TIG could pay off handsomely in quality results from your aluminum weldments. Additionally, consider factors such as equipment availability and budget constraints when making this decision; sometimes practicality trumps preference!

In conclusion, understanding these basic concepts around different types of aluminum welding will empower you as you embark on your next fabrication adventure! Armed with knowledge about MIG vs. TIG processes along with insight into how they fit within project scopes ensures that you'll make informed choices moving forward.

Essential Techniques for Success

Navigating the world of custom aluminum welding requires a solid understanding of essential techniques that can make or break your project. Whether you are tackling aluminum weldments for industrial applications or crafting artistic pieces, mastering preparation, equipment, and common pitfalls is crucial. Let’s dive into these vital aspects to ensure your welding endeavors are successful.

Preparation for Aluminum Weldments

Preparation is everything when it comes to aluminum welding; without it, even the best equipment won’t save you from a botched job. Start by thoroughly cleaning the surfaces to be welded; any oil, dirt, or oxidation can lead to weak joints in your aluminum weldments. Additionally, proper fit-up is key—ensuring that pieces align perfectly will help facilitate smoother welding processes and stronger bonds in aluminum to aluminum welding.

Before you begin, consider preheating thicker sections of aluminum; this can reduce the risk of cracking during the weld process. Also, having all necessary tools and materials ready will streamline your workflow and minimize downtime. Remember that good preparation sets the stage for high-quality custom aluminum welding results.

Proper Equipment for Aluminum Welding

Choosing the right equipment is paramount in achieving successful welds in custom aluminum projects. MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) are two popular types of welding processes used for aluminum; each has its own strengths depending on project requirements. For instance, MIG welding is often favored for speed and efficiency on larger projects, while TIG offers precision and control ideal for intricate designs.

When selecting equipment specifically tailored for alu weld tasks, ensure you have a suitable power source with adjustable settings to accommodate various thicknesses of materials being welded. Don’t forget about protective gear as well; high-quality gloves and helmets will keep you safe while working with powerful welding tools. Investing in proper equipment not only enhances quality but also makes the entire process more enjoyable.

Common Mistakes and How to Avoid Them

Even seasoned professionals can fall victim to common mistakes in custom aluminum welding that could easily be avoided with some foresight. One frequent issue arises from incorrect settings on your welder—using too high a voltage or feed speed can lead to burn-throughs or poor penetration in your welds. Always double-check machine settings before starting any project and adjust them based on material thickness.

Another pitfall involves neglecting post-weld treatment; failing to inspect finished joints can result in overlooking defects that compromise structural integrity over time. Make it a habit to perform thorough inspections after completing each weldment—this will save you headaches down the line! Lastly, don’t underestimate the importance of practice; honing your skills through trial and error will help avoid missteps associated with various welding types.

Industry Innovations in Welding

The world of custom aluminum welding is undergoing a remarkable transformation, driven by technological advancements that enhance efficiency and precision. With new techniques and equipment emerging, the landscape of aluminum welding is becoming more dynamic than ever. These innovations not only improve the quality of aluminum weldments but also expand the possibilities for various applications in industries ranging from automotive to aerospace.

Advancements in Welding Technology

Recent advancements in welding technology have revolutionized how we approach custom aluminum welding. For instance, laser welding has gained traction due to its ability to produce high-quality welds with minimal heat input, reducing distortion and improving overall strength. Additionally, developments in MIG and TIG welding processes have made it easier to achieve consistent results, ensuring that every aluminum weld meets rigorous standards.

Moreover, new filler materials are being developed specifically for aluminum to aluminum welding, enhancing the compatibility between different alloys and improving joint integrity. These innovations allow fabricators to tackle complex projects with confidence while reducing the likelihood of common issues associated with traditional methods. As technology continues to evolve, it's clear that modern solutions are paving the way for more efficient and effective custom aluminum welding.

The Role of Automation in Aluminum Welding

Automation is playing an increasingly vital role in enhancing productivity within the realm of custom aluminum welding. Robotic systems equipped with advanced sensors can perform precise welds at an impressive speed, minimizing human error and maximizing output quality. This shift towards automation not only streamlines production processes but also allows skilled welders to focus on more complex tasks that require their expertise.

Furthermore, automated systems can be programmed for various welding types—such as MIG or TIG—making them versatile tools for any fabrication shop specializing in aluminum weldments. By integrating automation into their operations, companies can reduce labor costs while increasing consistency across all projects involving aluminum to aluminum welding. As these technologies become more accessible, we can expect a surge in innovation across industries relying on custom solutions.

Sustainable Practices in the Welding Industry

The push for sustainability is reshaping practices within the custom aluminum welding industry as well. Companies are increasingly adopting eco-friendly techniques that minimize waste and energy consumption during fabrication processes involving alu welds. By utilizing advanced technologies like electric arc furnaces and energy-efficient equipment, manufacturers are significantly reducing their carbon footprint while maintaining high-quality standards.

Additionally, recycling scrap metal generated during production has become a standard practice among many fabricators specializing in aluminum welding projects. This not only conserves resources but also reduces costs associated with raw materials—an essential factor when considering long-term sustainability goals within competitive markets. As awareness of environmental responsibility grows among consumers and businesses alike, sustainable practices will continue to play a critical role in shaping the future of custom aluminum welding.

Custom Aluminum Projects: Case Studies

Custom aluminum welding has transformed various industries, showcasing its versatility and strength through innovative projects. From marine applications to architectural feats, the benefits of aluminum weldments are evident in a range of custom solutions. This section explores notable case studies that highlight the remarkable capabilities of aluminum welding.

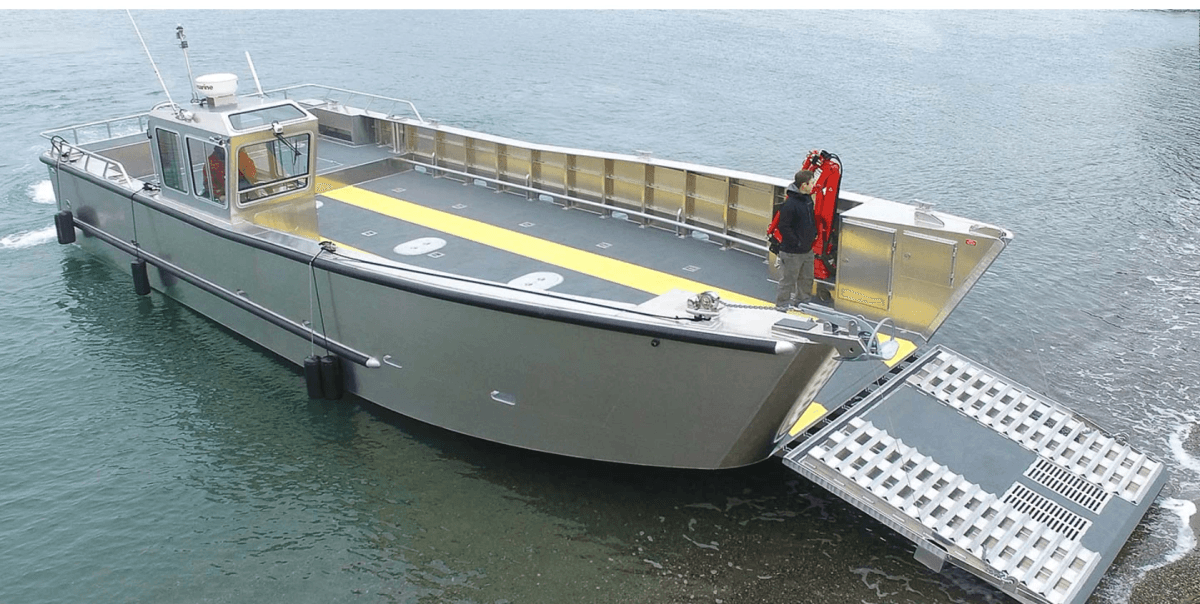

Weisidun Yacht: Marine Applications

The Weisidun Yacht is a prime example of how custom aluminum welding can elevate marine engineering. Designed for both performance and aesthetics, this yacht utilizes advanced aluminum to aluminum welding techniques to ensure lightweight construction without compromising strength. The MIG welding process was instrumental in creating seamless joints that enhance the vessel's hydrodynamics while maintaining durability against harsh marine environments.

In addition to performance, the yacht's design incorporates intricate details that showcase the artistry involved in custom aluminum welding. The skilled welders employed various welding types to create elegant curves and features that set this yacht apart from conventional designs. With its striking appearance and robust build, the Weisidun Yacht exemplifies how aluminum weldments can redefine luxury on water.

Architectural Marvels Using Aluminum Welding

Aluminum has become a staple in modern architecture due to its unique properties and aesthetic appeal. Numerous architectural marvels utilize custom aluminum welding for their structural integrity and design flexibility. Buildings like the iconic Sydney Opera House or contemporary skyscrapers often rely on efficient MIG and TIG welding techniques to achieve their stunning facades.

These structures demonstrate how custom solutions in aluminum fabrication allow architects to push boundaries in design while ensuring safety and stability through reliable welds. The ability to perform intricate designs with precision makes aluminum an ideal choice for ambitious projects that require both form and function. Ultimately, these architectural wonders reveal how effective aluminum to aluminum welding can transform visions into reality.

Inventive Products Born from Aluminum Weld

The world of consumer products has also benefited significantly from custom aluminum welding innovations. From lightweight bicycles to high-performance drones, manufacturers are leveraging the advantages of alu weld technology for better functionality and design appeal. These products often feature components made through advanced MIG or TIG welding processes, ensuring optimal performance while keeping weight at a minimum.

One standout example is high-end outdoor gear where durability is essential; companies use custom solutions involving robust yet lightweight welded frames for tents or camping equipment. The flexibility offered by different welding types allows designers to create unique shapes tailored for specific uses without sacrificing strength or reliability in their products. As a result, inventive items born from careful consideration of aluminum weldments continue to capture consumer interest across diverse markets.

Best Practices for Quality Assurance

When it comes to custom aluminum welding, ensuring the quality of welds is paramount. A well-executed aluminum weldment not only enhances the aesthetic appeal but also guarantees structural integrity. By adhering to best practices in quality assurance, manufacturers can significantly reduce defects and improve the longevity of their projects.

Inspecting Aluminum Welds

Inspecting aluminum welds is crucial for identifying potential flaws that could compromise the strength of a structure. Visual inspections should be conducted first, looking for signs such as porosity, cracks, or inconsistent bead patterns typically associated with improper welding techniques like MIG welding or TIG welding. Additionally, more advanced methods like ultrasonic testing or X-ray examinations can offer deeper insights into the integrity of aluminum to aluminum welding joints.

Regular inspections help ensure that all custom aluminum welding projects meet industry standards and client expectations. It’s important to document these inspections meticulously; this creates a trail that can be invaluable during future evaluations or audits. Ultimately, thorough inspection processes lead to higher-quality outcomes and enhanced customer satisfaction.

Ensuring Strength in Aluminum to Aluminum Welding

To ensure strength in aluminum to aluminum welding, it's essential first to choose the right filler materials and understand the specific alloy properties involved in your project. Different alloys respond differently during the welding process; hence selecting an appropriate filler material can enhance bond strength and performance under stress. Proper joint design also plays a vital role; utilizing techniques like groove designs can significantly improve load distribution across welded areas.

Furthermore, controlling heat input during the welding process is critical when working with aluminum weldments since excessive heat can lead to warping or weakening of joints. Techniques such as pulse MIG welding allow for better control over thermal input while still achieving strong bonds between pieces. Regularly testing for tensile strength post-weld ensures that your custom solutions stand up against real-world demands.

Certification Standards in the Welding Industry

Certification standards play an essential role in maintaining high-quality outcomes in custom aluminum welding projects across various industries. Organizations such as AWS (American Welding Society) provide guidelines that help manufacturers maintain consistent quality through rigorous training and certification processes for welders and inspectors alike. Adhering to these standards not only boosts credibility but also assures clients that you prioritize safety and reliability in every project involving complex aluminum weldments.

Moreover, certification helps companies stay updated on new technologies and best practices within different types of welding techniques—be it MIG or TIG—ensuring they remain competitive in an ever-evolving market landscape. Compliance with certification standards often opens doors for new business opportunities as clients increasingly seek partners who adhere strictly to recognized industry benchmarks for quality assurance.

By implementing robust inspection protocols, focusing on joint strength during fabrication processes, and aligning with certification standards within the industry, businesses engaging in custom aluminum welding can elevate their work's overall quality while minimizing risks associated with subpar welds.

Conclusion

In the ever-evolving landscape of manufacturing, custom aluminum welding stands out as a pivotal technique that blends creativity with functionality. As industries continue to innovate, the demand for high-quality aluminum weldments will only grow, ensuring that custom solutions remain at the forefront of fabrication projects. The future holds exciting possibilities for advancements in welding technology, particularly in how we approach aluminum to aluminum welding.

The Future of Custom Aluminum Welding

The future of custom aluminum welding looks promising, with ongoing advancements in both materials and techniques. Innovations such as enhanced MIG welding processes and automated systems are paving the way for more efficient production methods and higher-quality welds. As sustainability becomes a priority across industries, eco-friendly practices in aluminum welding will likely gain traction, promoting responsible manufacturing while maintaining performance standards.

Why Choose Custom Solutions for Your Projects

Opting for custom solutions in your projects allows you to tailor your fabrication needs precisely to your specifications. Custom aluminum welding not only provides flexibility but also ensures that each weld is optimized for strength and durability—essential factors when dealing with demanding applications like marine environments or architectural structures. By choosing specialized services that focus on quality assurance and expert techniques, you can ensure that your projects stand out both aesthetically and functionally.

Final Thoughts on Welding Types and Techniques

In conclusion, understanding the various welding types available is crucial when embarking on any project involving aluminum weldments. Whether you prefer MIG or TIG welding methods, each has its unique benefits suited for different applications within custom aluminum welding contexts. With proper preparation and an awareness of common pitfalls in the process, achieving reliable results from your aluminum to aluminum welding endeavors is entirely within reach.